Abbiamo scritto 30 articoli

At Riduttori Italia we design solutions, starting from your needs.

- giovedý 13 marzo 2025

Customized solutions are increasingly in demand in the field of power reducers: the ability to respond to the specific needs that companies express to achieve higher standards of durability, precision, and reliability is fundamental in choosing a partner for the development of high-power right-angle gear reducers.

Guide to Buying Industrial Gear Reducers for Large Machinery

- venerdý 7 febbraio 2025

If you work in the manufacturing sector, you surely know the importance of choosing the right reducer for your machinery. It is not just about finding a component that does its job but an element that influences performance, durability, and efficiency of your plant. In this article, we will explore the key aspects to consider when purchasing industrial reducers for large machinery to ensure a choice that brings long-lasting benefits to your equipment.

Custom Gearboxes: Who Benefits from Them?

- mercoledý 22 gennaio 2025

In modern industry, efficiency, precision, and durability are key factors for the success of businesses. The gearbox sector, in particular, has experienced significant development, with the demand for custom solutions growing to meet the specific needs of each production facility. In this context, Riduttori Italia positions itself as the ideal partner, thanks to its extensive expertise in designing custom gearboxes for various sectors, particularly the food industry and manufacturing.

Gear Reducers for Pasta Factories: Challenges and How to Solve Them

- martedý 7 gennaio 2025

The design of gear reducers for pasta factories is one of the most critical phases in the process of creating pasta production plants. The technical challenges that may arise during this phase require expertise and attention, as any error can compromise the reliability of the plant and, consequently, the quality of the final product. In this article, we will explore the main difficulties encountered in designing gear reducers for pasta factories and how Riduttori Italia, with its team of technicians, addresses them with advanced technical solutions.

Assembly of Gearboxes: Here's How to Find the Right Supplier.

- giovedý 12 dicembre 2024

The choice of the right supplier for gearbox assembly can be a crucial factor for the productivity and quality of a company’s final products. In this article, we analyze a real-life case that demonstrates the importance of a strategic partnership and provide guidance on how to identify the ideal partner.

Industrial Gearboxes for Railway Cables and Ballast Weights

- mercoledý 4 dicembre 2024

In the railway equipment sector, managing and controlling railway cables and ballast weights require highly efficient and reliable industrial components. Gearboxes, in particular, play a crucial role in ensuring the proper functioning of these critical applications. But what are the features that make gearboxes suitable for these applications? Let’s find out together.

Why Is My Industrial Gearbox Making Noise?

- martedý 12 novembre 2024

Industrial gearboxes are essential in many applications, ensuring efficient power transmission and precise motion control. However, in some cases, these devices may emit noises that indicate technical or maintenance issues. Understanding the causes of noise is essential not only for solving the problem but also for prolonging the life of the gearbox, improving energy efficiency, and reducing maintenance costs.

Railway Gearboxes: Custom Solutions for Train Axles

- lunedý 4 novembre 2024

In the railway sector, efficiency and safety are essential, and the choice of power transmission components—such as gearboxes for axles—plays a fundamental role. The train gearboxes are crucial in transferring power from the engine to the wheels, ensuring controlled and safe movement, even under heavy loads and intensive use conditions.

Precision Gearboxes for Robotics and Industrial Automation

- martedý 15 ottobre 2024

We are well aware that automation and robotics systems are constantly evolving, requiring increasingly sophisticated and reliable solutions to operate with precision. Precision gearboxes are fundamental in ensuring the efficiency of movements and operations, and thus are extensively evaluated during the design phase. In this article, we will explore how precision gearboxes are applied in robotics and industrial automation, focusing on their technical requirements and the advantages of their use.

Bearings in Industrial Gearboxes

- martedý 1 ottobre 2024

In the industrial context, large and medium-sized gearboxes play a crucial role in operations that require reliable mechanical power transmission. Bearings, as fundamental components, ensure the efficiency and durability of the gearbox. However, regular maintenance is essential to prevent failures and extend the system's lifespan. In this article, we will explore the importance of bearings and maintenance practices, also mentioning how Riduttori Italia, an expert team in gearbox overhaul, can step in when failures or wear occur.

Differences between Orthogonal Shaft Gearboxes and Planetary Gearboxes: Which to Choose?

- mercoledý 18 settembre 2024

When it comes to mechanical transmissions and speed reduction, two of the most commonly used solutions are right-angle gear reducers and planetary gear reducers. These two types of reducers have very different technical and structural characteristics, making them suitable for a wide range of industrial and non-industrial applications. But what are the main differences between the two? And how do you choose the most suitable reducer for your needs? Let's find out together in this article!

Preventive Maintenance of Gearboxes: How to Do It and Tips

- giovedý 5 settembre 2024

Preventive maintenance of gear reducers is a crucial element to ensure optimal operation and prolong the life of your industrial machinery. Riduttori Italia, with its extensive experience in the overhaul of gear reducers, is the ideal partner to provide you with professional and reliable service. In this article, we will share our experience regarding the importance of preventive maintenance and provide practical advice and best practices to keep your gear reducers in perfect working condition.

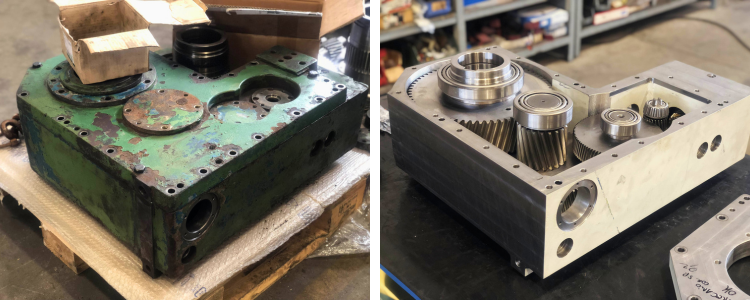

Renewal, or Bringing to New. We Are Specialists in Reducers

- lunedý 1 luglio 2024

It happens that complex machines, production lines, and important processing systems use specially designed reducers, tailored to specific power and torque requirements. It happens that these reducers malfunction or break down completely, affecting the overall performance of the entire line in which they are installed.

And yet it moves! How does a mechanical gearbox work?

- mercoledý 8 maggio 2024

Movement is a fundamental principle of the universe, essential for the functioning of many systems, both natural and man-made.

Everything moves, nothing stands still: from what moves at great speed to the tiniest elements that nevertheless - even if imperceptibly - move. This has always been the case, throughout human history.

Steelworks and Ironworks: where power is everything and it needs to be controlled

- venerdý 19 aprile 2024

The sector of Steelworks and Ironworks is a particular branch of industrial production that massively utilizes power reducers.

Large and complex mechanical systems and machines are installed in steelworks, which require power and torque to operate correctly and continuously, managing the applied load and ensuring the processes for which they have been designed.

Making gearboxes for rides and amusement parks is not a game. Our experience

- mercoledý 3 aprile 2024

For some time now at Riduttori Italia we have been dealing with gearboxes for rides, used in amusement park and amusement park attractions.

When to choose plastic gears

- mercoledý 4 ottobre 2023

Plastic gears have found widespread diffusion in recent years and increasingly intensive use in various industries: here some advices about their use.

The sugar industry: gearboxes for the resource of the future

- giovedý 29 giugno 2023

The sugar extraction and processing industry is a growing market. The demand for this material is constantly growing, and as a result producers find themselves increasing productivity and improving plant efficiency to meet it.

Gearboxes for mining industry: how technology helps

- mercoledý 14 giugno 2023

Mining sector is facing a major challenge: the increasing demand for raw materials. In addition, there are strict environment requirements to comply and a greater level of safety for workers to take into account. This situation has determined a revolution for components, which gearboxes are part of.

Special gearboxes for asphalt cutting machines: a solved case

- giovedý 16 febbraio 2023

Special solutions for special needs: here are our projects for asphalt cutting machines.

Gearboxes for the steel industry: how to carry out maintenance and revamping

- venerdý 13 gennaio 2023

Requirements and characteristics of gearboxes for shipyards and port

- lunedý 5 dicembre 2022

To fulfill naval and port sector needs we have developed several projects for the manufacture of gearboxes for winches and hoists.

Design and construction of gearboxes for mechanical attractions

- lunedý 3 ottobre 2022

In the amusement park and attractions industry each component must be designed and built to withstand strong stresses for a long time in particular conditions. Among the fundamental elements for the correct functioning of numerous attractions, gearboxes are also required to consider these particular application environments and other technical peculiarities in their designing.

The Future of Heavy Equipment is in Electric Transmission

- giovedý 23 giugno 2022

As is already the case for other sectors, theheavy equipment sector also winks more and more at the electric. Read more in the article.

Gearboxes for extruders: special applications

- giovedý 26 maggio 2022

Extruders machines require a high transmissible torque ratio in relation to the weight and size of the gearbox. Therefore the reducers applied to them must be able to withstand such a heavy application.

How to buy a large size reducer

- mercoledý 6 aprile 2022

In some specific branches there is a need to use a non-standard size gearboxes ro reduce the speed of movement of the machine to which they are connected to adapt it to the operating needs.

Gearbox revamping: what it is and how it works

- venerdý 19 novembre 2021

The revamping service is a gearbox overhaul, maintenance and renovation. The purpose is to restore the gearbox to its original conditions.

How To Choose The Right Gearbox For An Application

- martedý 19 ottobre 2021

If you have ever had to buy a gearbox and have some doubts about which one was the most suitable for your needs, or if you simply want to deepen the various fields of application of gearboxes, this article is for you.

What are Planetary and Parallel Axis Gearboxes

- martedý 23 marzo 2021

The two most popular types of gearboxes for industrial use are planetary gearboxes and parallel shaft gearboxes with spur gears. Choosing the right type of gearbox is essential to ensure optimal performance in the application. Here is a brief summary to make the process of choice easier.

How does gear reducers and multipliers work?

- venerdý 12 marzo 2021

Gear systems were invented by Leonardo Da Vinci in the early 1500s and are the basis for the operation of reducers and multipliers. In this article we will see what is the difference between a gear reducer and a gear multiplier, how they work and what are the possible practical applications.